We are able to design and execute many types of microfluidic devices and systems, and to build the necessary hardware and laboratory infrastructure for this type of equipment. Development of new solutions is carried out in full scope – from computer-aided design through design, prototype development to ready-to-use solution.

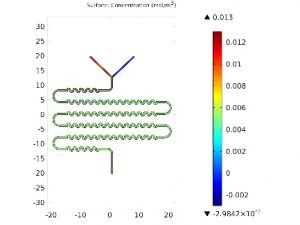

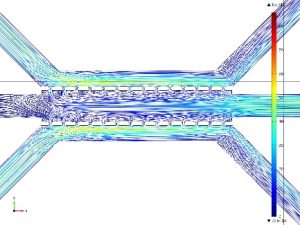

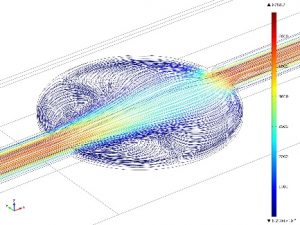

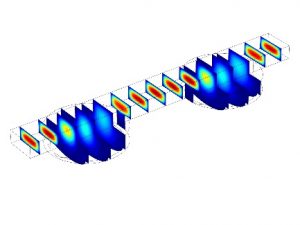

We usually start developing new solutions from computer simulations, which significantly reduce the time and cost of the project, and thus more tailor-made it to meet specific needs.

At this stage, we choose the most efficient and most efficient technology to produce a ready-made solution and, if necessary, develop a new technology. The technologies we use most often are:

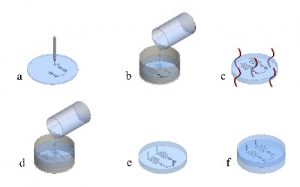

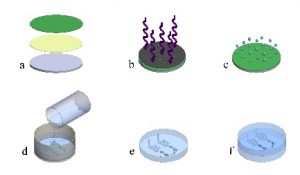

- photolitography,

- soft-litography,

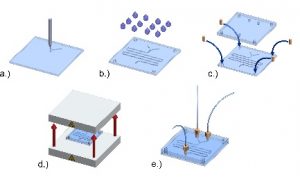

- micromilling.

Our technical background consists of state-of-the-art equipment necessary for the development and manufacture of microfluidic devices:

- spin coater (Laurell WS-650),

- mask aligner (SUSS MicroTec MJB4),

- plasma bonding system (diener ZEPTO-W6),

- CNC micromilling machine (Minitech Machinery MiniMill/3),

- Laboratory hydraulic press (Carver 4386).

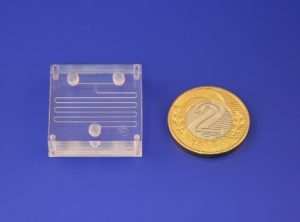

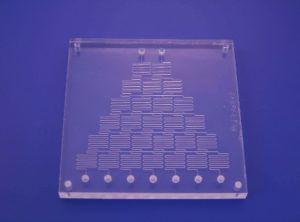

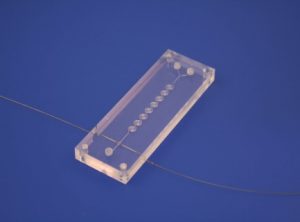

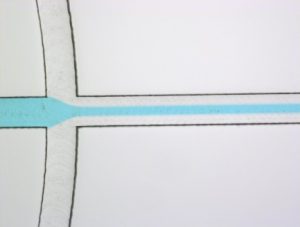

With the help of technology and available equipment we are able to perform both single micro devices such as:

- micromixers,

- microreactors,

- gradient generators,

- droplet generators,

- microfluidic systems for hydrodynamic focusing,

- microflow cells for spectrophotometric and electrochemical measurements,

as well as the complex μTAS microsystems and Lab-on-a-chip where various types of structures needed to perform chemical synthesis, chemical analysis or cell culture can be integrated. In addition, we are able to develop and produce the necessary equipment for handling microfluidic devices including:

-

micropumps,

-

multi-way micro valves,

-

microswitches (manual, automated),

-

dosing units for multi-hole plates.

We are able to develop solutions tailored for most applications in analytical chemistry, bioanalysis, medical diagnostics, microbiology and quality control.